SP1 or SP2?

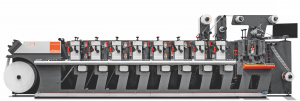

Etirama has two machine models with a maximum printing width of 350mm, which are: ETIRAMA SP1 and ETIRAMA SPS2.

But which would be the better option of the two? The answer is: The best option is the machine that best meets the profile of your business and, for that, in this article we highlight the differences between the two models.

Initially the SP1 machine comes out ahead with an investment value approximately 30% lower than the SPS2, maintaining the standard of printing quality, in addition to being a slightly more compact machine in terms of size and material passage, these points already become very attractive initially.

However, the biggest difference is the transmission part of the machines, and there the SPS2 model is superior. While the SP1 machine has a mechanical transmission with armored gearboxes and cardan shaft, in the SPS2 version the transmission is electronic, through servo motors, which allow electronic adjustments of the print register during the production process at a single point on the machine, through a touch screen, without the need to move to the printheads, in addition to greater stability in acceleration and deceleration ramps.

But SPS2 still accumulates a list of additional features compared to SP1. These are some of them:

- Greater print development (larger plate holder)

- Pre-registration system (360° rotation of the plate holder).

- Lift and larger coil diameter capacity

- Maximum print speed

- Anilox cylinder quick release system

- Larger list of accessories.

Both models are excellent options, as they carry the quality of being an Etirama brand product, and this automatically translates into production stability and print quality assurance. The other differences really must be analyzed according to the profile of each purchasing company, such as cost-benefit, return on investment, production volumes, among others.